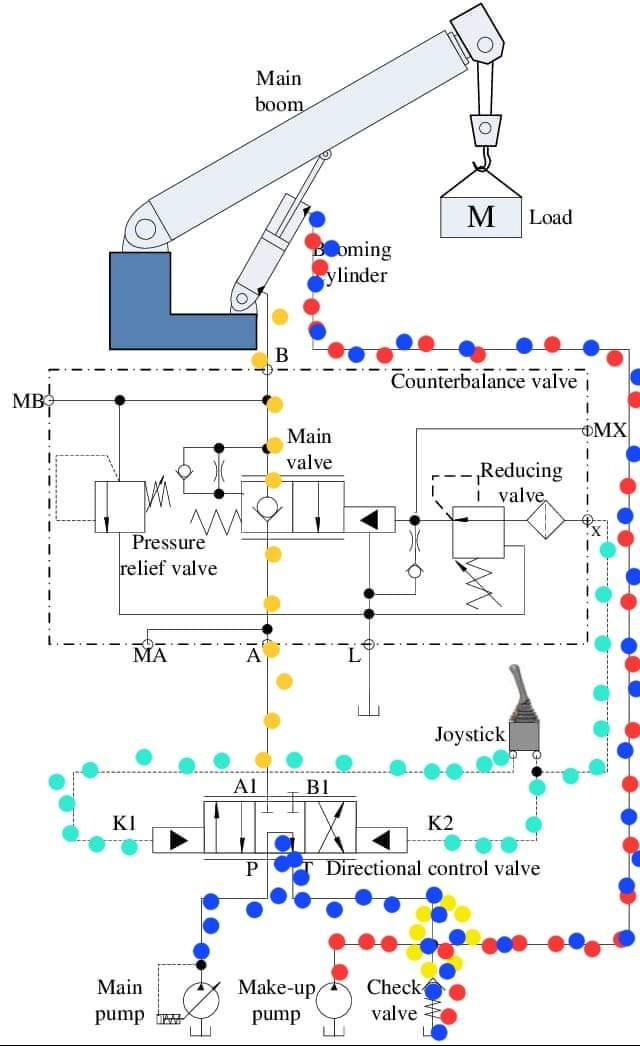

Directing system flow to the desired location and controlling pressure levels are core objectives and critical tasks of hydraulic systems. The application of hydraulic cartridge valves provides an effective solution for achieving this goal. This article will introduce the working principle of hydraulic cartridge valves, mainly through three aspects.

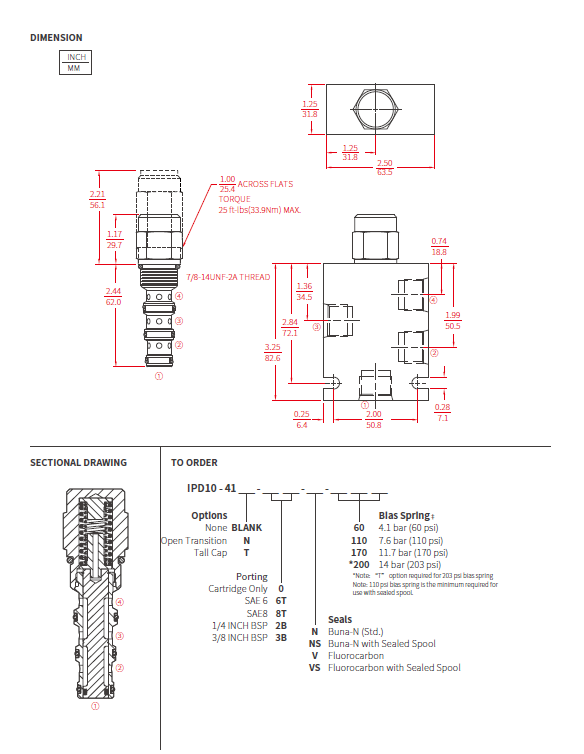

The structure of hydraulic cartridge valves is relatively simple, typically consisting of a base, a valve core, a valve seat, and a spring. The valve core is the main control component, whose shape matches that of the valve seat. The spring provides the valve core with reset force, allowing it to remain closed without external control. It is worth noting that the valve core is usually accompanied by appropriate seal rings to prevent leakage.

The working principle of hydraulic cartridge valve is relatively simple. Its working process can be briefly summarized as follows: When hydraulic oil enters the valve, the valve is closed due to the position of the valve core. When the system needs to divert flow, the control oil pressure pushes the valve core to the open position, thereby forming a flow channel. When the system needs to stop flowing, the valve core will return to the closed position due to the action of the spring.

Hydraulic cartridge valves have flexible application and easy installation, making them widely used in hydraulic systems. They can be used alone or as multi-way valves for complex control. In addition, due to the special structure of the cartridge valve, it can be replaced and maintained at any time during use, ensuring its reliability and stability.

In summary, hydraulic cartridge valves are a very practical hydraulic control component. Its structure is simple, performance is reliable, and its application range is wide, making it suitable for various needs in hydraulic systems.