In fluid control systems, maintaining a steady flow rate is crucial to ensure optimal performance and efficiency. A pressure compensated flow control valve is a sophisticated device that plays a vital role in achieving this objective. In this blog, we will delve into the pressure compensated flow control valve working principle, exploring how they regulate flow rates and contribute to stable operations.

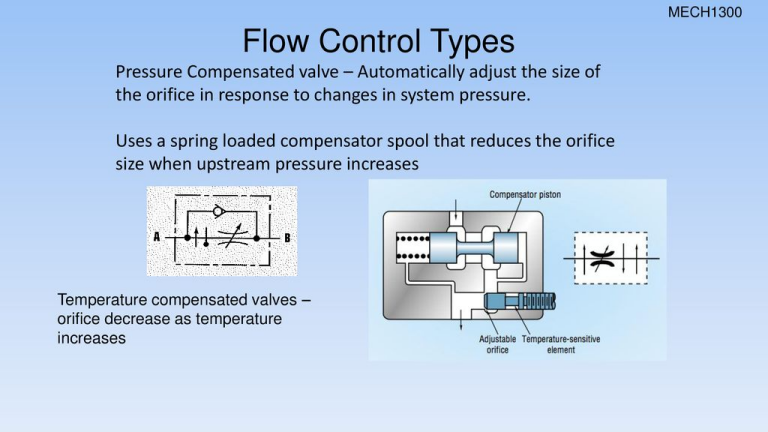

Pressure compensated flow control valves are specifically designed to maintain a consistent flow rate regardless of changes in the system pressure. They achieve this by utilizing a combination of mechanical and hydraulic components.

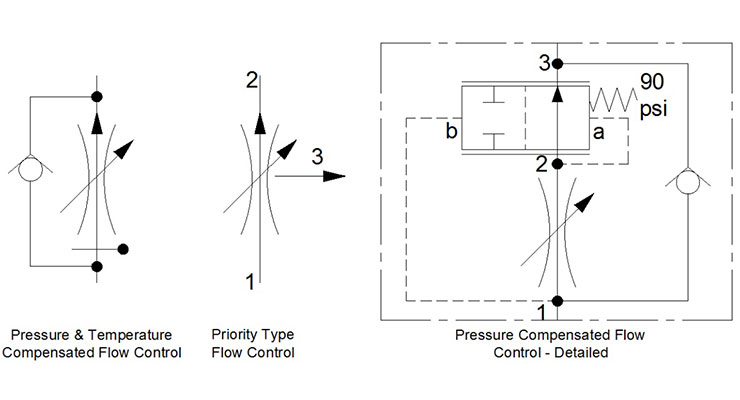

At the heart of a pressure compensated flow control valve is a pilot control mechanism. This mechanism constantly monitors the downstream pressure of the system. When the downstream pressure changes, the pilot control adjusts the size of the orifice through which the fluid flows. By doing so, it regulates the flow rate to keep it constant.

The spool and orifice design in pressure compensated flow control valves is crucial for their functionality. As the downstream pressure changes, the spool position within the valve shifts. This movement alters the opening size of the orifice, which in turn controls the flow rate. The spool's position is determined by the balance between the pressure from the pilot control mechanism and the pressure on the opposing side of the spool.

Pressure compensated flow control valves are equipped with a pressure sensing element, often in the form of a diaphragm or piston. This element continuously measures the downstream pressure and communicates the information to the pilot control mechanism. The pilot control uses this data to regulate the valve's orifice and maintain a consistent flow rate.

Pressure compensated flow control valves offer several advantages that make them ideal for various applications:

Stable Flow Rate: The ability to maintain a constant flow rate ensures consistent performance in fluid control systems, promoting smooth operations.

Compensation for Pressure Variations: These valves compensate for changes in downstream pressure, allowing for reliable flow control even in fluctuating system conditions.

Energy Efficiency: By stabilizing flow rates, pressure compensated flow control valves contribute to energy efficiency, reducing unnecessary power consumption.

Precise Control: The sophisticated pilot control mechanism enables precise flow rate adjustments, making these valves suitable for applications that require accurate flow control.

Pressure compensated flow control valves are critical components in fluid control systems, providing stable and reliable flow regulation. By utilizing a pilot control mechanism and pressure sensing element, these valves can maintain a consistent flow rate even in the face of varying system pressures. Their ability to ensure optimal performance and energy efficiency makes them an indispensable tool in a wide range of industries and applications. Understanding the working principle of pressure compensated flow control valves empowers engineers and operators to make informed decisions when selecting and implementing these valves in their systems.