The hot topic at the Messe 2013 in Hannover, Germany was "Industry 4.0".

The Fourth Industrial Revolution was first proposed by three German university professors at the Hannover Fair in 2011. Manufacturing accounts for 26% of the German national economy (value created). As a strategic development direction to enhance the traditional manufacturing industry, the 112-page implementation proposal was submitted by the project research team to the Ministry of Education and Research (BMBF), the Ministry of Economy (BMWi) and the Ministry of the Interior of the German Federal Government on October 2, 2012. (BMI). 200 million euros (about 1.6 billion yuan) has been allocated as the research and development funding for the first step. This is an organized revolution. The German Machinery and Equipment Manufacturing Association (VDMA), the Central Union of the Electronic Industry (ZVEI) and the Information and Communication New Media Association (BITKOM) have built a joint work platform for the first time in history, and started work in April 2013. One of the tasks is to coordinate Existing and pending research projects.

In Germany, the Industrial Revolution was so identified: for the first time, mechanization. Since the end of the 18th century, steam engines have gradually replaced human labor. At that time, the machine was driven by centralized power, and the power was transmitted to the machine from the power shaft in the sky through the belt. Mechanical manufacturing has begun to have a division of labor before, but it was not until the adoption of new power methods that it began to look like it is today. Machine tool manufacturing, as an industry, first started in England. "Made in Germany" is the warning sign (as an inferior product) that the British put on the German-made machine tools. The second time, assembly line production. Beginning in 1913, the American Ford used the assembly line to manufacture cars, standardized production, and the cost was greatly reduced, and the price dropped from 850US$ to 370US$. But at the same time, it also gives up a lot of personalization. Machines and assembly lines are gradually driven by electricity, which is easier to control. Third time, automation. Started in 1974. At that time a PLC (Programmable Logic Controller) made of integrated circuits was developed in a small company (Klaschka GmbH) in a small German place (Neuhausen im Enzkreis). Compared with the controller composed of relays, the control logic can be replaced and modified more conveniently and flexibly, which is the first step in the industrial application of microprocessor control. But at the time of the Cold War, no one thought that this little thing would change industrial production so much that it deserved to be called a revolution. In the future, the hardware level and integration level will continue to improve, and C language and higher-level programming languages will be adopted, which can describe not only simple AND or logical relationships, but also various complex control strategies (PID, self-adaptive, self-learning, etc. ), which are now widely used, almost everywhere.

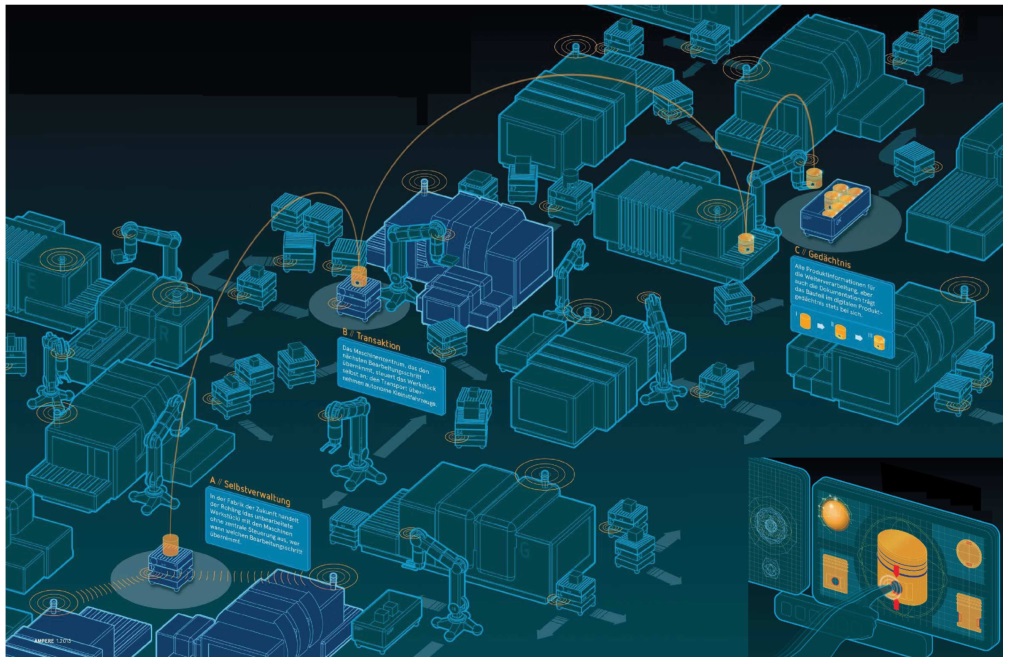

A typical example is the automotive industry. At the end of the 1980s, a research report "The Machine That Changed the World" completed by the Massachusetts Institute of Technology at a cost of US$ 5 million stated that the reason why Japan's auto industry was able to seize one-third of the world in 20 years market, in addition to "slim" (zero inventory) factories, the most important point is that assembly automation has been widely realized, and robot-assisted assembly has greatly improved quality and productivity. Therefore, it will be difficult for the automotive industry in the United States and Europe to compete with competition. However, the German auto industry has survived. One of the reasons is that all German robots are equipped with PLCs, and the programs can be flexibly changed and improved continuously. The goal of the fourth industrial revolution is the Intelligente Fabrik of factory intelligence.

Center: Bringing Web Technologies to Manufacturing.

Background: The situation that the manufacturing industry will face in the future - scarce resources, energy transition, changes in the age structure of employees, and globalization.

Technical basis: network and space distribution system, smooth communication, broadband speed up to 7000Mbit/s.

Features: flexible and changeable, high resource efficiency, consideration of ergonomics, and the most closely integrated enterprise with customers and business partners.

The envisaged changes are generally in the following aspects:

1) Integration of production technology and information technology

The current so-called digital factory first emphasizes the digitization of production planning and the extensive use of various computer-aided technologies: CAD, CAM, CIM, PPS (production planning control system), PDM, DMU (digital test model), PLM (product life Cycle management), etc., are mostly based on a relatively fixed, top-down centralized production control system. The new revolution emphasizes decentralization, reducing the degree of centralized control, increasing the independent control of production equipment, and closely connecting decentralized, independent and intelligent manufacturing equipment through the form of a network, with more open and active communication. The system structure is more dynamic and flexible, so that more optimization possibilities can be explored, and it is estimated that the production efficiency can be increased by 30%. Among them, CPS will play a central role. CPS——Cyber-Physical System, network entity fusion control system is a control system composed of sensors, control computers, actuators and networks. At present, in some fields, such as aviation, automobile, chemical production, infrastructure, energy, health, manufacturing, traffic control, entertainment and consumer electronics, etc., electronic combination control systems similar to CPS have appeared, but these systems At present, it is usually an embedded system, which places more emphasis on its computing control capabilities, while CPS places more emphasis on the connection between physical devices and computer networks. CPS is to use technical means to realize the extension of human control in terms of time and space, and its essence is the integration of people, machines and things. Therefore, it is also called a human-machine-material fusion system.

2) Product personalization

The factory with high production flexibility can cater to customers' requirements for product individuation, diversification, and constant change. It can manufacture batches of 1 product at the cost of mass production through modern means. In a sense, go back to before the first industrial revolution. Customers and factories communicate frequently, not only before signing a contract, but also after placing an order, design, processing, assembly, and commissioning. Thus, the customer can even change the details of his order during the production of the product. Although Rexroth Pump Factory has an annual output of more than 1 million units, there are more than a dozen categories, each category has more than a dozen specifications, and each specification has more than a dozen variable functions. Different pressure limiting, constant power values, etc. need to be set. Certainly. Therefore, there are tens of thousands of final products, and each batch is not many. Flexible management is extremely important.

3) Humanization of production

Through factory intelligence, more employees can have flexible working hours, so work is more at ease. Using the network, production can be decentralized and thus energy supply can be decentralized. Using the Internet, employees can work nearby, or even from home. They asked, if a large number of employees drive long distances to work every day, and then spend a lot of effort to save energy and reduce emissions in the factory, what is the practical significance?