Hydraulic pilot-operated directional control valves are essential components in many hydraulic systems. They play a crucial role in controlling the flow of hydraulic fluid, allowing machinery and equipment to operate efficiently. However, like any mechanical component, these valves can encounter issues over time. In this blog, we'll explore common problems associated with pilot-operated directional control valves and provide troubleshooting tips to help you address them effectively.

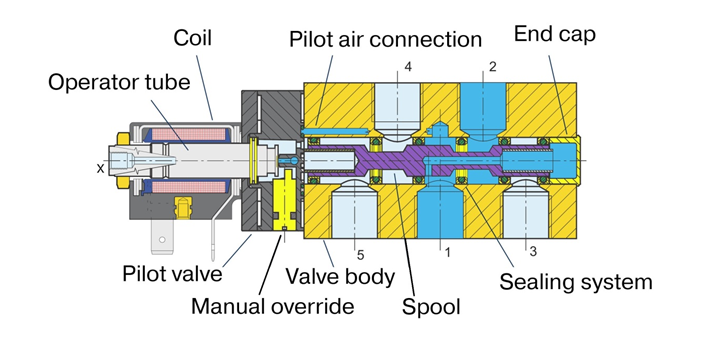

Before we dive into troubleshooting, let's briefly review what pilot-operated directional control valves are and how they work. These valves control the direction of hydraulic fluid flow within a system. They are commonly used in applications where precise control and rapid changes in direction are required.

Issue: One common problem with pilot-operated directional control valves is sticking or binding. This occurs when the valve spool or other moving parts become jammed, preventing proper operation.

Troubleshooting Tip: Inspect the valve for debris, dirt, or foreign objects that may be obstructing movement. Clean and lubricate the valve components as needed. If the problem persists, consider replacing worn or damaged parts.

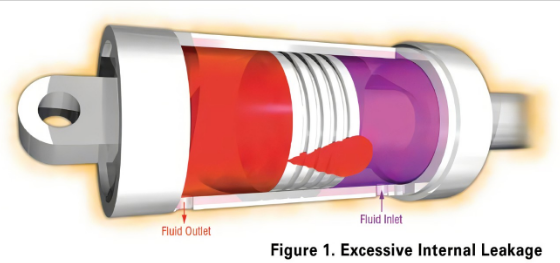

Issue: Hydraulic fluid leaks around the valve can lead to a loss of pressure and reduced system efficiency.

Troubleshooting Tip: Check for damaged seals, O-rings, or connections. Replace any worn or damaged components and ensure that all connections are properly tightened. Regularly inspect the valve for signs of leaks and address them promptly.

Issue: If your hydraulic actuators are not moving as expected or are operating erratically, it could be due to problems with the directional control valve.

Troubleshooting Tip: Examine the electrical and hydraulic connections to ensure they are secure and free from corrosion. Verify that the valve is receiving the correct signals from the control system. If the issue persists, consider testing the valve with a known-good unit to identify if it's a valve or control system problem.

Issue: Unusual noise or excessive vibration during valve operation can be indicative of underlying issues.

Troubleshooting Tip: Inspect the valve and surrounding components for loose fasteners, damaged parts, or worn-out bearings. Address any loose or damaged components and ensure that the valve is properly secured to its mounting.

Troubleshooting hydraulic pilot operated directional control valve is a critical skill for maintaining the efficiency and reliability of hydraulic systems. By addressing common issues such as sticking or binding, leaks, inconsistent actuator movement, and excessive noise or vibration, you can prevent downtime and costly repairs. Regular maintenance and periodic inspections can help identify and resolve potential problems before they disrupt your hydraulic system's operation. Always refer to the manufacturer's guidelines and consult with hydraulic experts when troubleshooting complex issues to ensure the safety and functionality of your hydraulic equipment.