Hydraulic systems play a crucial role in a wide range of industries, from manufacturing to construction and beyond. These systems rely on precision and control to perform their tasks efficiently and safely. One essential component that enhances the functionality of hydraulic systems is the direct-acting sequence valve. In this blog, we will explore the various ways in which direct-acting sequence valves enhance hydraulic systems, providing improved performance and reliability.

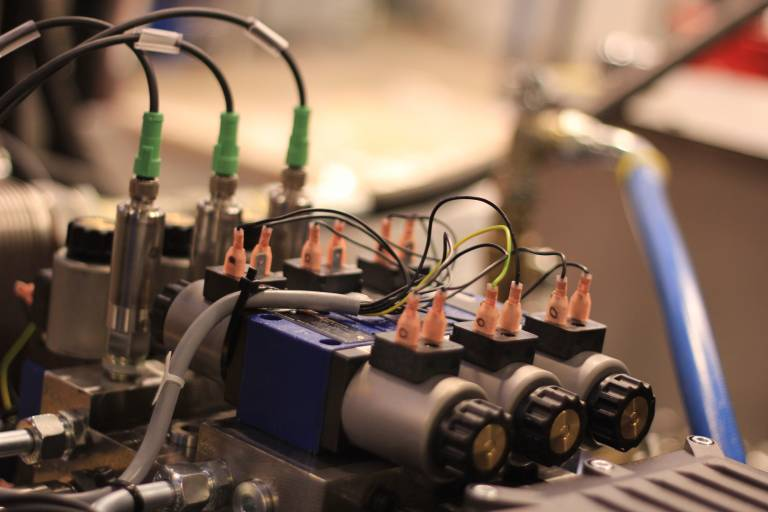

Before delving into the benefits, let's first establish what direct-acting sequence valves are and how they function within hydraulic systems. A direct acting sequence valve is a type of hydraulic valve that controls the sequence of operation in a hydraulic circuit. It allows fluid to flow from one hydraulic actuator to another in a specific order or sequence.

The valve achieves this by remaining closed until a predetermined pressure is reached at its inlet. Once this pressure is attained, the valve opens, permitting fluid to flow to the downstream actuator. This sequential operation is crucial in applications where precise control and coordination of hydraulic actuators are required.

One of the primary advantages of direct-acting sequence valves is their ability to prevent overloading of hydraulic components. When multiple actuators are operating within a hydraulic system, there is a risk of overloading if they all demand fluid simultaneously. The sequence valve ensures that each actuator receives fluid in the designated order, preventing overloads and potential damage to the system.

In applications where safety is paramount, such as heavy machinery or construction equipment, direct-acting sequence valves enhance safety by controlling the order of actuator movement. This prevents unintended movements that could lead to accidents or damage. For example, in a hydraulic press, the sequence valve ensures that the safety gate is lowered before the hydraulic ram can move, reducing the risk of injuries.

Energy efficiency is a key concern in modern hydraulic systems. Direct-acting sequence valves contribute to energy savings by ensuring that hydraulic actuators operate only when needed. By preventing unnecessary actuator movement, these valves help reduce energy consumption and, in turn, operating costs.

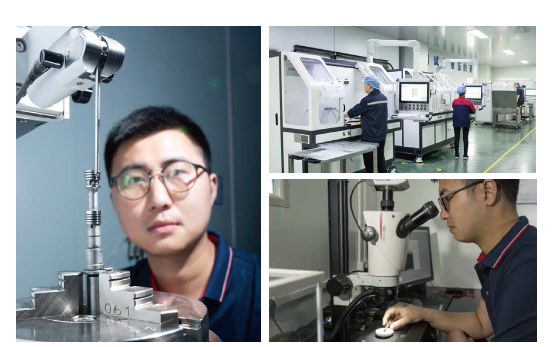

In applications requiring precise control, such as in aerospace or medical equipment, direct-acting sequence valves play a crucial role. They enable operators to control the sequence and timing of hydraulic movements with precision. This precision ensures that delicate or critical operations are carried out accurately, minimizing errors and rework.

Direct-acting sequence valves are indispensable components in hydraulic systems, offering a range of benefits that enhance performance, safety, and efficiency. By preventing overloading, improving safety, promoting energy efficiency, and enhancing precision, these valves contribute significantly to the reliability and effectiveness of hydraulic systems across various industries. When designing or maintaining hydraulic systems, considering the incorporation of direct-acting sequence valves can lead to improved overall performance and peace of mind.